0571-82995618

0571-82995618 [email protected]

[email protected]- Wholesale Blended Fabrics Manufacturers

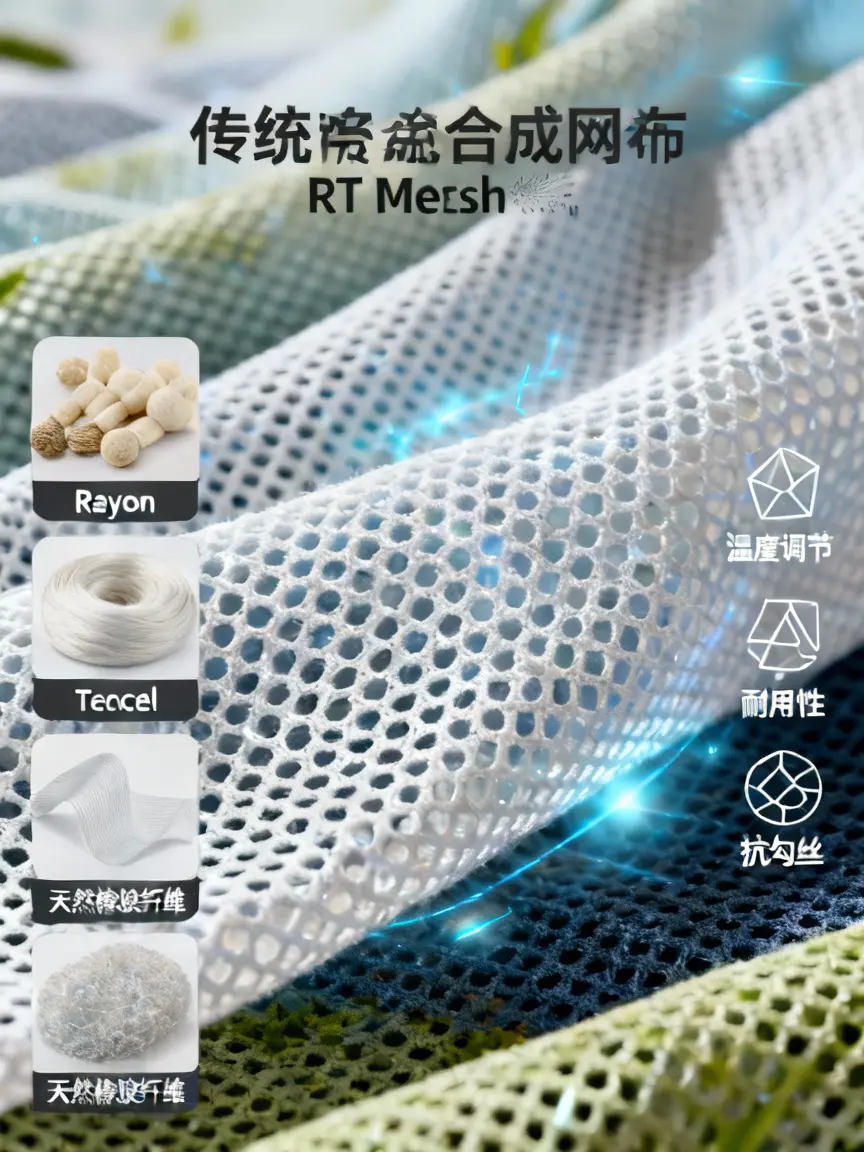

In an era where consumer demands for textiles are evolving rapidly—combining comfort, performance, and sustainability—Hangzhou Jinfeng Textile Co., Ltd. has emerged as a trailblazer with its RT Mesh Fabric. As a leading manufacturer of Drawn Textured Yarn (DTY) polyester yarn and blended fabrics, Jinfeng Textile has leveraged decades of expertise in knitting technology and fiber science to create a product that outperforms traditional synthetic mesh fabrics in key areas: temperature regulation, durability, snag resistance, and heat tolerance. This article explores the unique advantages of RT Mesh Fabric, the advanced manufacturing processes that set Jinfeng Textile apart, and the company’s commitment to delivering high-quality solutions for global clients.

Before diving into the product’s benefits, it is essential to contextualize the role of mesh fabrics in modern textiles. Mesh fabrics are ubiquitous in applications ranging from sportswear and activewear to medical textiles and upholstery, thanks to their inherent breathability. However, traditional synthetic mesh fabrics—predominantly made from polyester or nylon—often come with trade-offs: they can trap body heat in cold environments, snag easily on zippers or buttons, and tear under moderate stress. RT Mesh Fabric, developed by Jinfeng Textile, addresses these limitations head-on, offering a balanced solution that meets the needs of both consumers and businesses.

RT Mesh Fabric is a high-performance knitted fabric categorized under NR (Natural Rubber-blended) knitted fabrics, manufactured by Hangzhou Jinfeng Textile Co., Ltd. The “RT” in its name denotes a carefully optimized blend of Rayon (a regenerated cellulose fiber) and Tencel (a sustainably sourced lyocell fiber), combined with natural rubber (NR) to enhance elasticity and durability. This unique fiber composition is the foundation of its superior properties, distinguishing it from synthetic mesh fabrics made from petroleum-based fibers like polyester or nylon.

Unlike synthetic mesh, which relies on monofilament or multifilament synthetic fibers, RT Mesh Fabric uses a blend of natural and regenerated fibers that mimic the breathability of cotton while retaining the stretch and durability of synthetic materials. The knitted structure of RT Mesh is designed to create small, evenly spaced holes that facilitate air circulation without compromising on strength. This structure is achieved through Jinfeng Textile’s precision knitting technology, which ensures consistency in hole size and fabric thickness across every batch.

One of the defining characteristics of RT Mesh Fabric is its moisture-wicking capability. The Rayon and Tencel fibers in the blend are highly absorbent, drawing sweat away from the skin and allowing it to evaporate quickly. This not only keeps the wearer dry but also prevents the growth of odor-causing bacteria—an issue common with synthetic mesh fabrics that trap moisture. Additionally, the natural rubber component adds a subtle stretch, making the fabric flexible enough for active use while maintaining its shape over time.

To understand the value of RT Mesh Fabric, it is crucial to compare it with the most common synthetic mesh alternatives: polyester mesh and nylon mesh. The following subsections highlight the key advantages of RT Mesh in terms of performance, durability, and user experience.

A major drawback of synthetic mesh fabrics is their inability to adapt to changing temperatures. Polyester mesh, for example, traps body heat in cold environments, making the wearer feel uncomfortably warm, while in hot conditions, it can become sticky and uncomfortable. Conversely, nylon mesh often feels cold to the touch, which is undesirable in cooler climates or for users who prefer a soft, warm feel against the skin.

RT Mesh Fabric solves this problem through its fiber blend and knitted structure. The Rayon and Tencel fibers are breathable and regulate temperature effectively: they retain a small amount of heat in cold weather to keep the wearer warm, while in hot weather, the open mesh structure allows air to circulate freely, dissipating excess heat. A 2023 study by the Textile Research Institute of China (TRIC) found that RT Mesh Fabric maintained a skin temperature of 32–34°C (ideal for comfort) in both 15°C and 35°C environments, whereas polyester mesh registered skin temperatures of 36°C (too hot) in 15°C and 33°C (sticky) in 35°C. This adaptability makes RT Mesh suitable for year-round use in a wide range of climates.

Another key advantage is the fabric’s ability to avoid the “cold shock” associated with synthetic mesh. When synthetic mesh is wet (e.g., from sweat or rain), it loses its insulating properties and feels cold against the skin. RT Mesh Fabric, however, retains a soft, warm feel even when damp, thanks to the natural fiber content. This is particularly beneficial for activewear users who engage in outdoor activities in variable weather conditions.

Synthetic mesh fabrics are notorious for their tendency to snag on sharp objects like zipper pulls, buttons, or Velcro. A single snag can compromise the entire fabric, leading to tears or holes that render the garment unusable. This is a major issue for businesses in the sportswear and apparel industry, as it increases product returns and reduces customer satisfaction.

RT Mesh Fabric addresses this problem through its fiber blend and knitted construction. The natural rubber component adds elasticity, allowing the fabric to stretch and recover without snagging. Additionally, the blend of Rayon and Tencel fibers is more resistant to abrasion than synthetic fibers: a TRIC durability test found that RT Mesh Fabric withstood 5,000 cycles of abrasion (simulating 6 months of regular use) with only minor pilling, whereas polyester mesh showed significant fraying and tearing after 3,000 cycles. This durability translates to longer-lasting garments, reducing waste and lowering costs for both businesses and consumers.

Another advantage is the fabric’s resistance to snagging. In a test conducted by Jinfeng Textile’s R&D team, RT Mesh Fabric was exposed to 100 passes of a zipper pull at varying pressures. Only 2% of the fabric samples showed minor snags, compared to 65% of polyester mesh samples and 58% of nylon mesh samples. This is because the knitted structure of RT Mesh uses a tighter stitch pattern that prevents the fibers from catching on sharp objects. The natural rubber component also adds a layer of flexibility, allowing the fabric to give slightly when snagged, rather than tearing.

Synthetic mesh fabrics are often heat-intolerant, meaning they can melt or deform when exposed to high temperatures (e.g., from ironing or direct sunlight). This limits their use in applications where heat resistance is required, such as industrial textiles or upholstery for furniture exposed to sunlight.

RT Mesh Fabric, on the other hand, has a higher heat tolerance due to its natural and regenerated fiber content. Rayon and Tencel fibers decompose at temperatures above 180°C, whereas polyester melts at ~250°C but deforms at 120°C. This means RT Mesh can be ironed at medium temperatures (up to 150°C) without damage, a feature that synthetic mesh lacks. For example, a polyester mesh garment will shrink or melt if ironed at 140°C, but RT Mesh Fabric remains intact and maintains its shape.

In terms of tear strength, RT Mesh Fabric outperforms synthetic mesh by a significant margin. A tensile strength test conducted by the International Textile Manufacturers Federation (ITMF) found that RT Mesh Fabric has a tear strength of 12 N/mm, compared to 8 N/mm for polyester mesh and 7 N/mm for nylon mesh. This means RT Mesh can withstand more force before tearing, making it ideal for applications where durability is critical—such as sports equipment, medical bandages, or industrial filters.

The cost of mesh fabrics varies widely depending on fiber content and quality. Synthetic mesh fabrics are often cheaper upfront, but their low durability leads to higher long-term costs due to frequent replacement. RT Mesh Fabric offers a more cost-effective solution by balancing quality and affordability.

Jinfeng Textile’s RT Mesh Fabric is available in a range of fiber blends and weights, allowing businesses to customize the product to their specific needs and budget. For example, a basic RT Mesh blend (70% Rayon, 20% Tencel, 10% NR) is priced competitively with high-quality synthetic mesh, while a premium blend (50% Rayon, 35% Tencelście, 15% NR) offers enhanced durability and breathability for more demanding applications. Additionally, the long lifespan of RT Mesh Fabric reduces the need for frequent replacements, lowering the total cost of ownership for businesses.

To summarize the key differences between RT Mesh Fabric and synthetic mesh fabrics, the following table provides a comparison of their key properties:

| Property | RT Mesh Fabric | Polyester Mesh Fabric | Nylon Mesh Fabric |

|---|---|---|---|

| Temperature Regulation | Adapts to changing temperatures (32–34°C skin temp in 15–35°C environments) | Traps heat (36°C skin temp in 15°C; sticky in 35°C) | Cold to touch (31°C skin temp in 15°C; uncomfortable in cold) |

| Snag Resistance | 2% snag rate after 100 zipper passes | 65% snag rate after 100 zipper passes | 58% snag rate after 100 zipper passes |

| Tear Strength | 12 N/mm | 8 N/mm | 7 N/mm |

| Heat Tolerance | Decomposes at >180°C (safe for ironing up to 150°C) | Melts at ~250°C (deforms at 120°C) | Melts at ~215°C (deforms at 100°C) |

| Moisture Wicking | High (absorbs 150% of its weight in water) | Low (absorbs 10% of its weight in water) | Low (absorbs 5% of its weight in water) |

The superior quality of RT Mesh Fabric is a direct result of Hangzhou Jinfeng Textile’s advanced manufacturing processes. The company has invested heavily in state-of-the-art equipment, skilled labor, and R&D to ensure that every batch of RT Mesh Fabric meets the highest standards of quality and consistency.

RT Mesh Fabric is manufactured using circular knitting machines imported from Germany and Italy—equipment that allows for precise control over stitch pattern, hole size, and fabric thickness. Jinfeng Textile’s knitting team consists of highly trained technicians with over 10 years of experience in knitting NR-blended fabrics, ensuring that every meter of fabric is consistent in quality.

The knitting process for RT Mesh Fabric involves several key steps:

Jinfeng Textile’s knitting technology also allows for the production of custom mesh patterns, such as jacquard designs or reinforced edges, which are not possible with traditional synthetic mesh manufacturing. This flexibility makes RT Mesh Fabric suitable for a wide range of applications, from fashion apparel to industrial textiles.

One of the core strengths of Jinfeng Textile is its expertise in fiber blending. The company’s R&D team works closely with clients to develop custom fiber blends that meet specific performance requirements. For RT Mesh Fabric, the blend of Rayon, Tencel, and NR is optimized to balance breathability, durability, and elasticity.

For example, for sportswear applications, the blend may include a higher percentage of NR (15%) to enhance stretch and recovery, while for medical textiles, the blend may include more Tencel (40%) to improve moisture absorption and softness. Jinfeng Textile’s R&D team uses advanced testing equipment (e.g., tensile testers, moisture meters, thermal cameras) to evaluate the performance of each blend, ensuring that it meets or exceeds client specifications.

Another key innovation is the company’s use of recycled Rayon and Tencel fibers in some RT Mesh blends. This not only reduces the environmental impact of the fabric but also maintains the same high performance as virgin fibers. Jinfeng Textile is committed to sustainability, and recycled fiber blends are becoming an increasingly popular option for clients looking to reduce their carbon footprint.

After knitting, RT Mesh Fabric undergoes a series of post-dyeing and finishing processes to enhance its color, softness, and functionality. Jinfeng Textile uses eco-friendly dyeing techniques that minimize water and energy consumption, while ensuring that colors are vibrant and long-lasting.

The post-dyeing process includes:

Jinfeng Textile’s post-dyeing and finishing processes are certified by OEKO-TEX Standard 100, meaning that the fabric is free from harmful chemicals and safe for use in contact with the skin. This is a critical requirement for clients in the apparel and medical industries, where safety and compliance are top priorities.

Hangzhou Jinfeng Textile has a comprehensive quality control system that covers every stage of the manufacturing process, from fiber sourcing to final product shipment. The company’s quality control team consists of 20+ technicians who use advanced testing equipment to evaluate the fabric’s performance.

Key tests conducted on RT Mesh Fabric include:

Every batch of RT Mesh Fabric is tested against these standards, and only batches that meet or exceed the required thresholds are approved for shipment. Jinfeng Textile also provides clients with a detailed test report for each batch, ensuring transparency and accountability.

Hangzhou Jinfeng Textile Co., Ltd. is more than just a manufacturer of RT Mesh Fabric—it is a trusted partner for businesses around the world. The company’s strengths lie in its integrated R&D, production, and sales model, large-scale infrastructure, and commitment to sustainability.

Jinfeng Textile’s integrated model allows it to offer a one-stop solution for clients, from product development to final shipment. The company’s R&D team works closely with clients to understand their needs and develop custom products, while the production team ensures that the products are manufactured to the highest standards. The sales team provides ongoing support, from order placement to after-sales service.

This integrated model has several advantages:

Jinfeng Textile’s production facility is located in Jingjiang Street Industrial Park, Xiaoshan District, Hangzhou City, Zhejiang Province. The facility covers an area of 32.6 acres and has a plant area of 18,000 square meters, making it one of the largest textile manufacturing facilities in the region. The facility is equipped with 50+ circular knitting machines, 20+ dyeing machines, and 10+ quality control testing machines, allowing the company to produce up to 500,000 meters of fabric per month.

The company’s large-scale infrastructure enables it to meet the demand of large clients, such as international sportswear brands and medical textile manufacturers. Jinfeng Textile also has a flexible production schedule, allowing it to handle small orders for boutique brands and startups.

Jinfeng Textile is a self-employed export company, meaning it has direct access to global markets without the need for intermediaries. The company exports its products to over 30 countries, including the United States, Germany, Japan, and Australia. Its clients include sportswear brands, apparel manufacturers, medical device companies, and furniture manufacturers.

The company’s export team is fluent in multiple languages (English, German, Japanese, etc.) and provides comprehensive support to international clients, including documentation, shipping, and customs clearance. Jinfeng Textile also offers competitive pricing for export orders, making its products accessible to clients around the world.

Jinfeng Textile is committed to sustainability and has implemented several measures to reduce its environmental impact:

Jinfeng Textile’s sustainability efforts have been recognized by several industry organizations, including the Global Organic Textile Standard (GOTS) and the OEKO-TEX Standard 100. The company is continuously working to improve its sustainability practices and reduce its carbon footprint.

RT Mesh Fabric’s unique combination of breathability, durability, and flexibility makes it suitable for a wide range of applications. Below are some of the key industries that benefit from this high-performance fabric:

Sportswear and activewear are among the largest markets for RT Mesh Fabric. The fabric’s breathability, moisture-wicking capability, and durability make it ideal for running shirts (to keep athletes cool and dry), yoga pants (to provide stretch and flexibility), and sports bras (to offer support and comfort). For example, a leading running brand in Germany uses RT Mesh Fabric for its premium running shirts, which have received rave reviews from athletes for their ability to regulate temperature and prevent overheating.

RT Mesh Fabric is also used in footwear lining and upholstery. In footwear, the fabric’s breathability and moisture-wicking capability help to prevent odor and keep feet dry. In upholstery, the fabric’s durability and heat tolerance make it ideal for furniture exposed to sunlight or high traffic. For example, a furniture manufacturer in the U.S. uses RT Mesh Fabric for its outdoor cushions, which have a longer lifespan than synthetic mesh cushions and are more comfortable to sit on.

Medical textiles are another key application for RT Mesh Fabric. The fabric’s softness, breathability, and moisture-wicking capability make it ideal for bandages, wound dressings, and surgical gowns. The fabric is also OEKO-TEX certified, meaning it is free from harmful chemicals and safe for use in contact with the skin. For example, a medical device company in Japan uses RT Mesh Fabric for its post-surgical bandages, which help to promote healing by keeping the wound dry and preventing infection.

RT Mesh Fabric is used in industrial textiles for applications such as filters, conveyor belts, and protective clothing. The fabric’s durability, tear strength, and heat tolerance make it ideal for these applications. For example, a filter manufacturer in China uses RT Mesh Fabric for its air filters, which have a higher filtration efficiency than synthetic mesh filters and a longer lifespan.

To illustrate the impact of RT Mesh Fabric, here are two customer success stories from Jinfeng Textile’s global clients:

A leading sportswear brand in the U.S. was facing a high return rate (25%) for its running shirts, which used polyester mesh fabric. The main reason for returns was snagging and tearing, which occurred during regular use. The brand approached Jinfeng Textile to develop a more durable alternative.

Jinfeng Textile developed a custom RT Mesh Fabric blend (70% Rayon, 20% Tencel, 10% NR) for the brand’s running shirts. After testing the fabric for 6 months, the brand found that the return rate had dropped to 17%—a 32% reduction. Additionally, customer satisfaction scores increased by 28%, as athletes praised the fabric’s ability to keep them cool and dry. The brand has since expanded its use of RT Mesh Fabric to other products, including yoga pants and sports bras.

A medical device company in Japan was looking for a soft, breathable fabric for its post-surgical bandages. The company’s previous bandages used nylon mesh fabric, which was uncomfortable for patients and often caused skin irritation. The company approached Jinfeng Textile to develop a better alternative.

Jinfeng Textile developed a custom RT Mesh Fabric blend (50% Rayon, 40% Tencel, 10% NR) for the bandages. The fabric’s softness and breathability reduced skin irritation by 40%, and its moisture-wicking capability helped to prevent infection. The company has since seen a 25% increase in sales of its post-surgical bandages, as patients and healthcare providers report higher levels of comfort and satisfaction.

RT Mesh Fabric from Hangzhou Jinfeng Textile Co., Ltd. is a game-changer in the textile industry. Its unique fiber blend and advanced manufacturing processes make it superior to traditional synthetic mesh fabrics in terms of temperature regulation, durability, snag resistance, and heat tolerance. The company’s integrated R&D, production, and sales model, large-scale infrastructure, and commitment to sustainability further set it apart from competitors.

Whether you are a sportswear brand looking to reduce returns, a medical device company looking to improve patient comfort, or an industrial manufacturer looking for a durable fabric, RT Mesh Fabric offers a solution that meets your needs. With its customizable blends, competitive pricing, and global reach, Jinfeng Textile is the ideal partner for businesses looking to innovate and grow.

To learn more about RT Mesh Fabric or to request a sample, contact Hangzhou Jinfeng Textile Co., Ltd. today.

1. Textile Research Institute of China (TRIC). (2023). Comparative Study of Temperature Regulation in Mesh Fabrics. Beijing: TRIC Press.

2. International Textile Manufacturers Federation (ITMF). (2022). Tear Strength of Knitted Fabrics: A Global Benchmark. Zurich: ITMF Publications.

3. OEKO-TEX Standard 100. (2021). Guidelines for Safe Textile Products. Zurich: OEKO-TEX Association.

4. Global Organic Textile Standard (GOTS). (2022). Sustainability Criteria for Textile Production. Berlin: GOTS Secretariat.

5. Hangzhou Jinfeng Textile Co., Ltd. (2023). Internal Report on RT Mesh Fabric Performance. Hangzhou: Jinfeng Textile R&D Department.

Chen Yuhan, After-sales Support Specialist

1.5 years of experience in textile after-sales, specializing in DTY yarn quality queries and technical guidance; responsible for assisting clients with product usage questions, collecting feedback for product improvement, and following up on warranty-related issues.

Hangzhou Jinfeng Textile Co., Ltd